PATTERN DEVELOPMENT PROCESSES (Home Sewing Patterns)

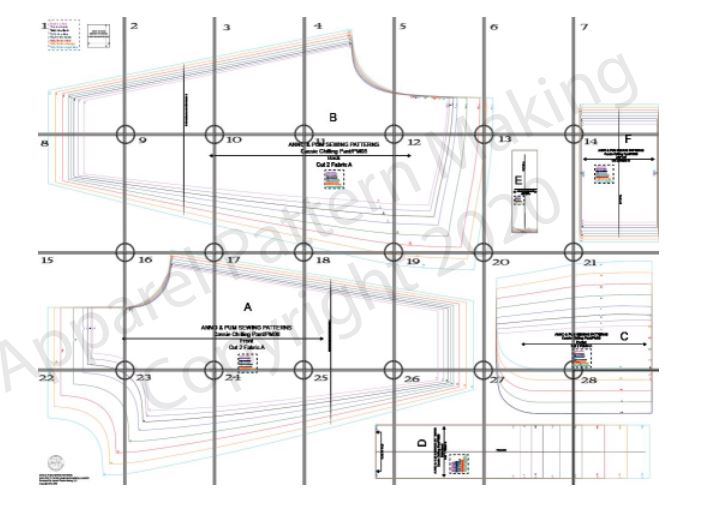

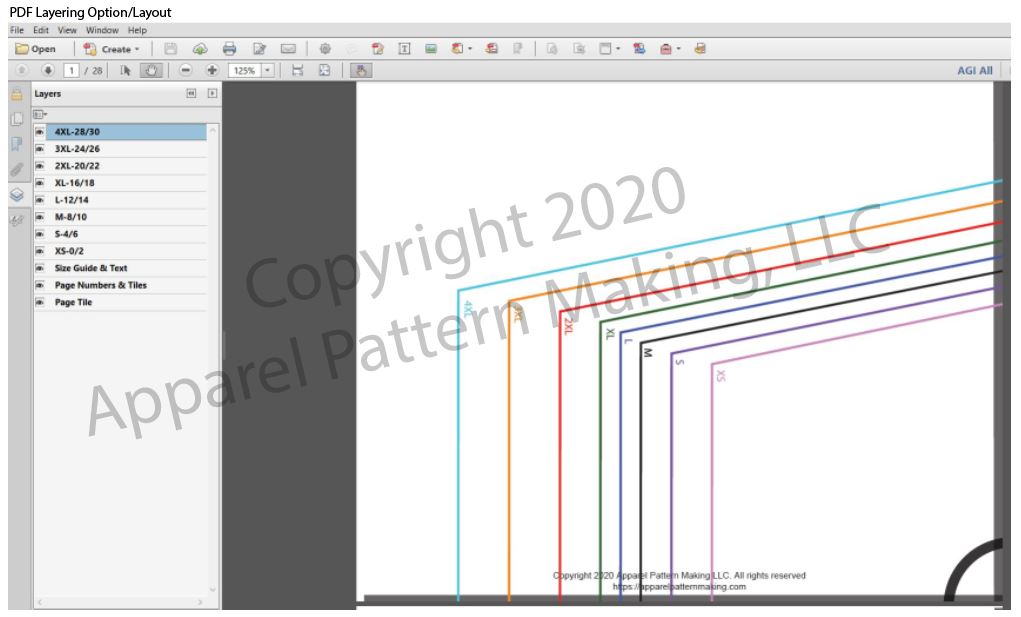

ILLUSTRATOR/PDF SEWING PATTERN LAYOUTS – Single size and graded size patterns can be set up in various page size layouts for use as a PDF file type. So your customers can download and print pages to assemble page layouts for cutting and sewing of your designs. PDF’s can be saved in various sizes (Letter, A4, A0, Projector, and others) To get your pattern PDF design layout/s started today, click APM Home Sewing Pattern PDF Layout Forms to print forms, fill out, and email to APM with your design submission information.